Comprehending Gauge Fillet Weld: A Comprehensive Overview for Welders

Comprehending Gauge Fillet Weld: A Comprehensive Overview for Welders

Blog Article

Fillet Weld Design Techniques: Optimizing Joint Efficiency and Aesthetic Appeal for Structural Honesty

In the realm of structural design and construction, the importance of fillet weld layout approaches can not be overemphasized. These methods play a critical duty in not just guaranteeing the efficiency and architectural integrity of joints however also in improving the general aesthetic appeals of the ended up item. By diligently thinking about aspects such as weld profile optimization, material selection, joint preparation techniques, welding procedure performance, and visual improvement approaches, engineers and producers can attain a harmonious balance in between capability and appearance in their bonded frameworks. The fusion of these aspects not only causes robust joints yet also elevates the aesthetic charm of the end product.

Weld Account Optimization

Attaining an ideal weld profile includes a meticulous factor to consider of elements such as product density, joint arrangement, welding placement, and desired welding speed. Furthermore, the selection of proper welding criteria, such as voltage, current, and travel speed, is essential in regulating the shape and measurements of the fillet weld. Using sophisticated welding strategies, such as pulse welding or robotic welding, can further improve the weld account to fulfill specific style demands and high quality requirements.

In essence, weld account optimization is an essential aspect of fillet weld style that directly affects the total performance and dependability of bonded joints in architectural applications.

Material Option Considerations

When considering product option for fillet weld design, the compatibility of the base steels is an important aspect influencing the architectural stability of the joint. It is important to pick products that not only bonded with each other effectively but additionally have comparable mechanical residential or commercial properties to make sure the load is uniformly distributed between the weld and the base metals. Welding materials with greatly various homes can bring about issues such as tension concentrations, early joint failing, or cracking.

Furthermore, the setting in which the bonded framework will operate need to be taken into consideration when picking materials. Elements like corrosion resistance, temperature fluctuations, and exposure to chemicals can all influence the longevity and efficiency of the weld joint. By selecting materials that are suitable for the desired application and setting, the overall sturdiness and integrity of the welded joint can be considerably boosted.

For that reason, extensive consideration of product compatibility and environmental variables is vital in guaranteeing the weld joint's strength, sturdiness, and overall architectural stability.

Joint Preparation Methods

Considering the vital role material choice plays in guaranteeing the structural integrity of fillet weld joints, it is essential to carry out exact joint prep work techniques that enhance the link between the base steels. Joint preparation is a vital action that straight influences the high quality and toughness of the weld.

Furthermore, proper fit-up of the joint is necessary to make certain uniform circulation of the welding material and prevent flaws like incomplete infiltration or extreme buildup. Beveling the sides of the base steels can navigate to this website develop a groove that enables deeper weld penetration and a more powerful bond. In addition, tack welding the components in position before the final weld helps keep alignment and decreases distortion throughout the welding procedure. By meticulously adhering to these joint prep work methods, welders can improve the overall efficiency and aesthetics of fillet weld joints while making sure architectural sturdiness.

Welding Refine Performance

Reliable welding processes are crucial for accomplishing optimum productivity and quality in fillet weld construction. One essential facet of enhancing welding procedure performance is choosing the appropriate welding strategy. Variables such as product type, joint design, and welding position should be carefully taken into consideration to figure out the most appropriate approach. Processes like gas steel arc welding (GMAW) and flux-cored arc welding (FCAW) are frequently utilized for fillet welds due to Learn More Here their convenience and speed.

In addition, guaranteeing correct tools setup and maintenance is critical for effective welding. Routine calibration of welding devices, assessment of consumables, and upkeep of welding lanterns can prevent downtime and revamp, ultimately conserving time and sources. In addition, using proficient welders with know-how in the specific welding procedure being made use of can dramatically influence effectiveness. Trained welders are much more experienced at changing criteria, repairing problems, and keeping constant weld top quality.

Aesthetic Improvement Methods

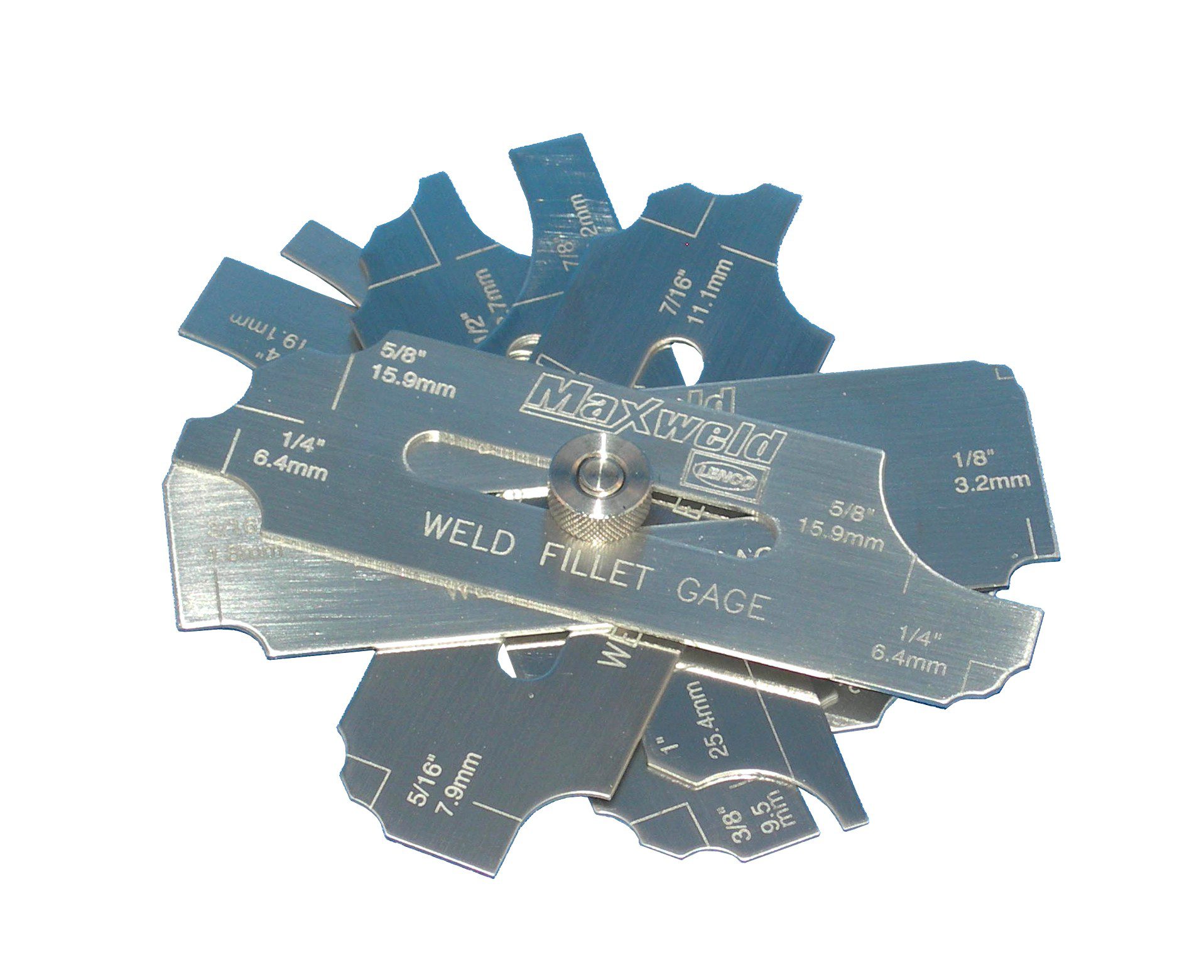

To maximize the top quality of fillet weld manufacture, carrying out aesthetic enhancement techniques can play a crucial function in making sure precision and accuracy during the welding procedure. Aesthetic help such as weld size evaluates and amplifying lenses can assist in examining weld accounts and dimensions properly. By integrating these visual enhancement approaches right into the welding process, welders can attain not just structurally audio fillet welds but additionally aesthetically enticing outcomes that meet sector criteria.

Final Thought

To conclude, optimizing fillet weld design includes careful factor to consider of weld account, material option, joint prep work, welding procedure effectiveness, and visual improvement approaches. By carrying out these techniques, architectural honesty can be improved while likewise achieving aesthetic appeal. It is essential to prioritize both efficiency and looks in fillet weld layout to ensure the total quality and sturdiness of the joint.

By meticulously taking into consideration factors such as weld profile optimization, product choice, joint prep work techniques, welding procedure effectiveness, and visual visit this site enhancement approaches, producers and designers can achieve an unified equilibrium in between capability and look in their welded frameworks.In the realm of fillet weld style, optimizing the weld profile plays a crucial function in guaranteeing structural integrity and efficiency. The weld profile, which includes the dimension and shape of the weld cross-section, directly impacts the circulation of stress and load-bearing capability within the joint. It is important to select materials that not just weld with each other effectively but likewise possess similar mechanical buildings to make certain the lots is equally dispersed between the weld and the base steels - Gauge Fillet Weld.In conclusion, maximizing fillet weld design involves careful factor to consider of weld account, material choice, joint preparation, welding procedure efficiency, and visual enhancement approaches

Report this page